CapabilitiEs

By engineering, manufacturing, and assembling in-house, we're able to meet the needs of an ever-changing marketplace. In building for commercial and military aircrafts, land-based turbines, medical equipment, fuel injection, telecommunication, and diesel engines, our dedication to precision is ever-present.

When life depends on delivering precision, you can depend on Chucking Machine Products.

Sub-Assembly & Final Assembly

At Chucking Machine Products, we have the expertise to produce high quality machined components as well as sub-assembly and final assembly of your parts. Our in-house capabilities allow us to offer our customers a one-stop shop for their complete contract assembly. This is one of the areas that sets us apart in the manufacturing marketplace.

Engineering Services

Chucking Machine Products takes every measure necessary to ensure that a quality part is produced each and every time. Before we cut the first chip, our Engineering Department breaks down your part into its manufacturing steps and generates operational blueprints. We utilize the latest technology in 3D modeling to ensure that quality is engineered throughout the process. In addition, we offer technical assistance at the design level to ensure your product is manufactured cost effectively.

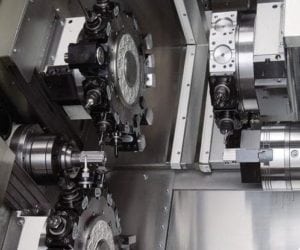

Manufacturing

CMP continually adapts better manufacturing systems, which allows for ongoing growth with our customers. We have lowered manufacturing costs by reducing non-value added operations, improving process flow on the shop floor and increasing our production efficiencies. Setting up cellular manufacturing—both generic and custom—has also equipped us to shorten cycle times for new and existing product.

5 Axis Milling

7 Axis Turning

3D PRINTING

CHUCKING MACHINE PRODUCTS 3D PRINTING CAPABILITIES

Chucking Machine Products is capable of 3D printing and has a Mark Forged model Mark Two 3D printer.

Build Volume:

5.2” x 6.0” x 12.6”

Base Materials:

Onyx – A micro carbon fiber filled nylon.

Nylon - An unfilled thermoplastic.

Continuous Fiber Reinforcement Materials:

Carbon Fiber - An ultra-high-strength continuous fiber. When laid into an Onyx base material, it can yield parts as strong as 6061-T6 Aluminum.

Kevlar - A specialized continuous fiber known for its energy absorption and extreme toughness. When laid into an Onyx base material, it yields extremely impact-resistant parts.

High Strength High Temperature (HSHT) Fiberglass – Has high strength (nearly equal to 6061-T6 Aluminum) and strength in high temperatures but not as stiff as Continuous Carbon Fiber, Onyx parts.

Fiberglass – A material capable of yielding parts 10x stronger than ABS when laid into an Onyx composite base material.

Engineering at Chucking Machine Products is capable of taking a customer’s 3D CAD step file and convert it into a 3D printed part or, if necessary, create a 3D CAD model from customer’s drawings then convert into a 3D printed part.

3D PRINTING

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Quality Control Services

When life depends on quality, you can depend on CMP. We certify to the International Organization for Standardization ISO 9001/2000. CMP has a Quality Department second to none in the industry, allowing us to ship many of our customer's parts directly to their stores.

Coordinate Measuring Machine

CMP: the future of precision manufacturing

When life depends on delivering precision,

You can depend on Chucking Machine Products