Materials

Careers

Please fax resumes to Fax#: 847-678-1269 or email merrigan@chucking.com

If you are looking for a career in manufacturing with room for advancement and a steady future, please submit your resume for consideration.

We are always looking for set-up men, cnc operators, cad operators using SolidEdge and other manufacturing positions.

A career at Chucking Machine Products means being at the forefront of technology in commercial and military aircraft, land based turbines, medical, fuel injection, telecommunication, and diesel engines. Our employees have also undertaken work on satellite and missile programs, as our 48,000 square foot, climate-controlled facility allows for optimal production.

Since our beginning, there’s no doubt we’ve seen some changes—technological evolution takes place at an amazingly accelerated rate. It always has. As a recognized leader in Ultra-Precision Machined Components, Chucking Machine Products is no different. But a big part of why we’re good at what we do, and are therefore able to remain competitive, is a result of the people who are doing it.

And that’s one thing that hasn’t changed.

That’s Where You Come In. Because it’s Our People That Make the Difference.

v A Tight-Knit Team of Professionals A family-owned company since 1957, Chucking Machine Products has over 70 employees, many of who have been with the company for more than 20 years!

v Employee Recognition—what you do matters. Whether for Aerospace, Landbase Turbine, Diesel Engine or the Medical industry, Chucking Machine Products leads the way in sophisticated design and innovative-machining. Which means there’s always room for growth.

v Tuition Reimbursement. As an employee of Chucking Machine you get what you give and are encouraged to foster specialized skills. Active members looking to further their education are reimbursed for class costs.

v Health Insurance. Our employees are looked after and valued. In addition to Health Insurance, Chucking Machine offers an On-Site Annual Health-Screening.

v CHALLENGING YOU TO BECOME BETTER Chucking Machine Employees are among some of the nation’s most Elite Team of Professionals, assuming responsibility for the highly technical jobs most shops aren’t equipped or qualified to take on.

v 401-K/Profit Sharing, Plus— Paid Holidays Ho-Ho-Ho.

v Highest Standards of Safety. Chucking Machine Products is a pleasant, climate-controlled environment to work in and has been awarded for its safety programs. And hey, the bathrooms are clean too.

v The Little Things! Chucking Machine Products is big on the little things. Christmas Party, Pizza Lunches, Thanksgiving Turkeys, Complimentary Coffee, the Glorious Lunch Truck,

v FITNESS . We have an Exercise Room right on our premises (to work off the pizza parties)

Always Moving Forward Work You Can Believe In

We are currently accepting applications. However, you will not be considered unless we have an opening that fits your qualifications.

Please fax resumes to Fax#: 847-678-1269 or email merrigan@chucking.com

Manufacturing

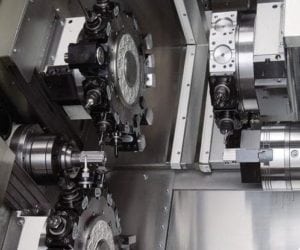

CMP continually adapts better manufacturing systems, which allows for ongoing growth with our customers. We have lowered manufacturing costs by reducing non-value added operations, improving process flow on the shop floor and increasing our production efficiencies. Setting up cellular manufacturing—both generic and custom—has also equipped us to shorten cycle times for new and existing product.

5 Axis Milling

7 Axis Turning

3D PRINTING

CHUCKING MACHINE PRODUCTS 3D PRINTING CAPABILITIES

Chucking Machine Products is capable of 3D printing and has a Mark Forged model Mark Two 3D printer.

Build Volume:

5.2” x 6.0” x 12.6”

Base Materials:

Onyx – A micro carbon fiber filled nylon.

Nylon - An unfilled thermoplastic.

Continuous Fiber Reinforcement Materials:

Carbon Fiber - An ultra-high-strength continuous fiber. When laid into an Onyx base material, it can yield parts as strong as 6061-T6 Aluminum.

Kevlar - A specialized continuous fiber known for its energy absorption and extreme toughness. When laid into an Onyx base material, it yields extremely impact-resistant parts.

High Strength High Temperature (HSHT) Fiberglass – Has high strength (nearly equal to 6061-T6 Aluminum) and strength in high temperatures but not as stiff as Continuous Carbon Fiber, Onyx parts.

Fiberglass – A material capable of yielding parts 10x stronger than ABS when laid into an Onyx composite base material.

Engineering at Chucking Machine Products is capable of taking a customer’s 3D CAD step file and convert it into a 3D printed part or, if necessary, create a 3D CAD model from customer’s drawings then convert into a 3D printed part.

3D PRINTING

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Quality Control Services

When life depends on quality, you can depend on CMP. We certify to the International Organization for Standardization ISO 9001/2000. CMP has a Quality Department second to none in the industry, allowing us to ship many of our customer's parts directly to their stores.

Coordinate Measuring Machine

CMP: the future of precision manufacturing

When life depends on delivering precision,

You can depend on Chucking Machine Products